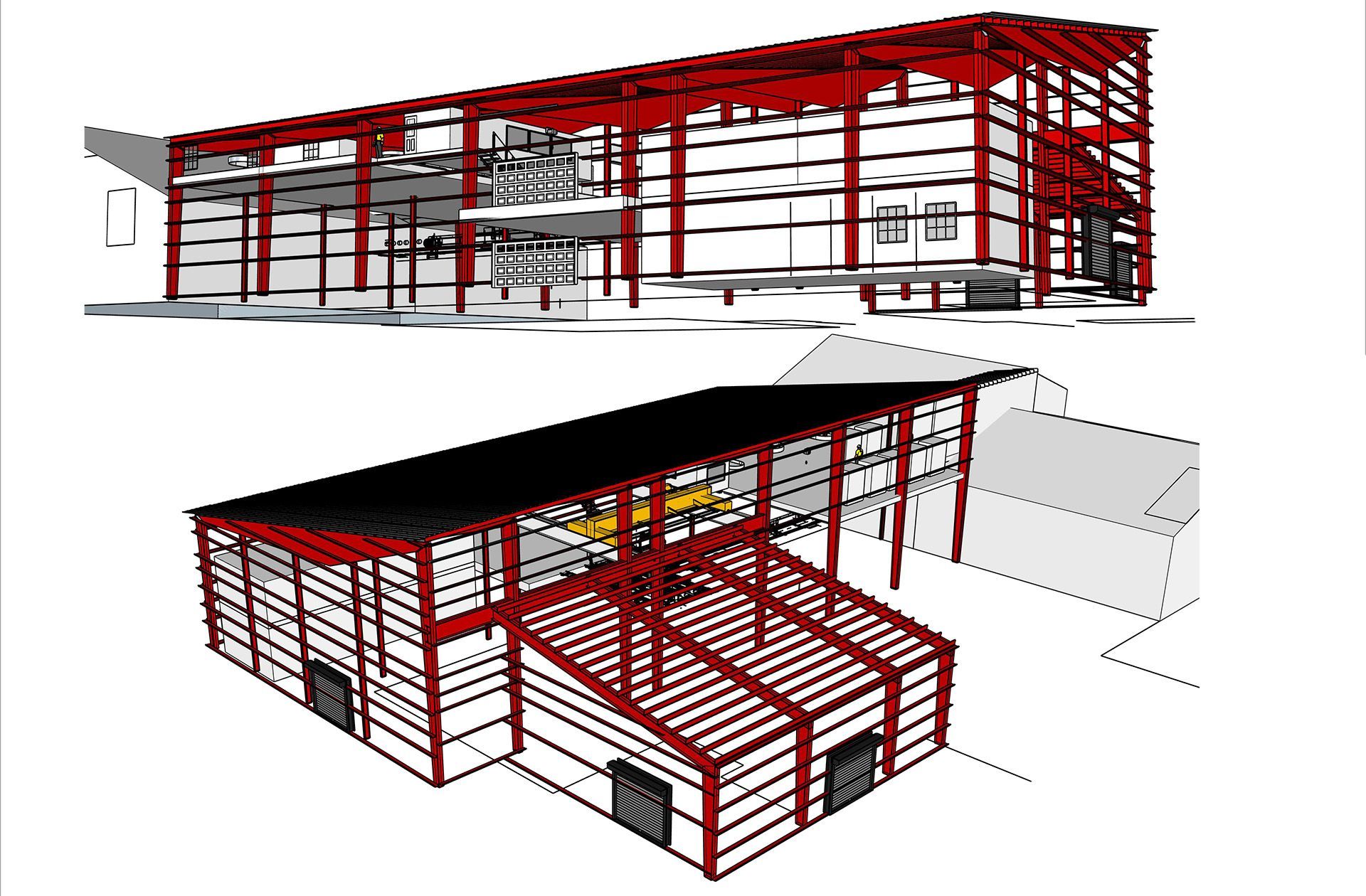

Eco-friendly buildings start with using steel construction

Steel’s strong performance, durability and endless ability to be recycled make it one of the most sustainable construction materials on the planet.

The signs of environmental change are all around us. Global temperatures and sea levels are rising, and carbon emissions levels are approaching all-time highs. The United Nations (UN) Environment Programme has reported that the building and construction sector accounted for 36% of final energy use and 39% of energy and process-related carbon dioxide (CO2) emissions in 2018. Manufacturing building materials, and products such as steel, cement and glass, made up 11% of that total. In practical terms, it takes about 30 years to offset the embodied carbon impact of a typical new construction building.

As clients demand more environmentally friendly building processes that leave a smaller carbon footprint, sustainable construction has become a topic builders can no longer ignore. Trends in construction indicate that building codes and regulations are going to follow suit, requiring companies to be more conscientious about how they build and the practices they use.

As a provider of steel metal structures – a building material being manufactured in a greener way and replacing traditional concrete structures as the natural material of choice – Summit Steel Buildings continues to take the lead in this eco-friendly trend. Implementing more sustainable building methods, with less carbon-heavy materials, provides an enormous opportunity for the construction industry to reduce the impact on global change. Frank Melo, director at the company, reflects on his 15 years of experience with pre-engineered steel building throughout North America to explain the advantages of sustainable building and how the company has been contributing to greener future for both business and our planet.

Sustainability starts with sourcing – local, natural materials

My belief in the value of using steel for commercial buildings comes from my experience in construction where I’ve seen the vast difference in the amount of waste created with steel versus conventional brick and wood. Steel buildings use less material, use more environmentally friendly materials, can be built much quicker and produce much less waste. The fact that everything used in steel construction can be recycled provides peace of mind to our clients. They not only get a high-value, high-functioning building that looks great, but they understand how the building is contributing to more sustainable practices with a much smaller carbon footprint – during construction and with each year in operation thereafter. The future is clear that sustainability will remain an important factor in business decision-making.

The types of materials we use and how they are sourced are major contributing factors. Sustainability continues to be a major focus as we, and so many other companies, improve the ways we can make our operations greener.

Fortunately, steel manufacturing is becoming more efficient in using less energy to make more. The steel used in any of our final buildings can be made faster than traditional materials and is value-engineered using current best practices. Modern fabrication technology provides greater precision, productivity and safety.

Natural metals – Cold-formed steel is the main metal used in our pre-engineered panels, although other all-natural metals, such as aluminum, copper and zinc, are also used in various components. These metals contribute to overall sustainability through their long lifecycle, their ability to be recycled and incredible durability. Cold-formed steel is typically harder and stronger (in tensile strength) with less surface imperfections. It has a smoother polished surface finish and uses less energy to create – processing is done at or near room temperature. The cold-forming process produces a higher yield and steel with more uniformity and more well-defined edges and corners. It’s also more resistant against tension breaking and deformation. These advantages mean we order less material and create less waste when building. Its higher carbon content traps it within the materials rather than releasing it into the environment resulting in a much lower carbon footprint.

High-quality steel allows us to create a wide variety of innovative engineering and building designs to aid in providing natural light and insulation. Another popular trend we’re finding is using pre-weathered steel or stainless steel that eliminates the need for painting, thus eliminating more chemicals in the construction process. Read our related article on what makes steel such an environmentally friendly building material.

Local sourcing – As much as the “shop local” mentality has affected the retail industry, manufacturing and construction companies like ours are reaping the benefit of obtaining their materials closer to jobsites. We’ve optimized the approach to our supply chain by fabricating our buildings throughout multiple factories strategically located across North America using locally made steel. We support local manufacturing as much as possible. This ensures we can deliver closer to destination or use more efficient transportation via ports on the east or west coast. We produce our pre-engineered panels in a modular fashion that can be manufactured offsite and then assembled on site to reduce excess transportation and excessive waste.

Local manufacturing reduces fuel-heavy transportation and contributes to more dependable construction schedules. Domestically sourced products reduce the risk of potential shipping delays and improve our overall lead times. Because time is money (especially in construction), we can manufacture materials locally in 30 days (compared to three or four months overseas) and can ensure more effective delivery to the site where construction can begin. Control is a big advantage of sourcing material domestically. Delays affect the project’s budget and make scheduling more complicated. If coming from another country, so many factors – such as schedule, cost and logistics – are so much more difficult to control and affect every aspect of construction that follows.

Sustainability is embedded throughout every project

We try to reduce the carbon footprint of our buildings beginning with each partner throughout the project – from the architect who selects the materials, to the engineers who put it together and the teams involved in the actual construction. Each stage of actual construction further contributes to making the project smarter for the environment. The architect is crucial in selecting materials created using fewer carbon emissions. Because “superstructure” materials, such as concrete and steel, represent 20% or more of annual global greenhouse gas emissions (mostly due to the sheer quantity of finished materials used in global construction), selecting responsible products and processes is important in reducing our cumulative carbon footprint.

Summit Steel Buildings tries to further reduce it by using less energy throughout the rest of construction phase.

Our materials are pre-assembled and then erected onsite to reduce fuel costs and to minimize employee, equipment and material travel. Our teams create less waste to further help make the entire project greener. These measures contribute to carbon savings. Our ultimate goal is to create net-zero carbon buildings – using steel goes a long way to achieving that.

Sustainability and carbon savings aren’t the only benefit

Metal building construction uses intelligent engineering and a variety of sustainable products that are beneficial to the environment as well as your current and future budget needs.

- Long lifespan with high durability:

- Pre-engineered steel buildings are highly durable and have a long lifespan.

- Your existing metal structure can be easily modified or expanded instead of being replaced once you outgrow your existing footprint.

- Metal buildings require minimal, if any, ongoing maintenance.

- Built using less materials:

- Compared to traditional wood and brick construction, steel reduces total building weight and footprint – requiring less raw materials and resources – while accommodating longer spans by using smaller member sections.

- Uses less energy consumption:

- Less building volume due to lower floor-to-floor heights creates more efficient climate control and allows for easier integration of mechanical systems.

- More natural light and higher occupant comfort is the result of larger windows allowed by using steel framing.

- Endless recyclability:

- Steel buildings can be easily deconstructed to be reused or relocated.

- Well-established and high demand for steel scrap ensures every piece will be recycled in the future.

- High salvage value for all steel components makes it an investment that retains its value.

We have learned valuable lessons while looking at ways to incorporate sustainability into our operations. While better for the environment, building with steel is also better for your business. You can lower your building costs even as you’re contributing to better and more viable planet.

Building with steel leads to a more sustainable future

The nature of steel construction ensures a quicker build, using less energy, with greener materials. Every small contribution leads to a big impact that grows the economy while helping to protect the planet’s environment… and public health as a consequence. We believe steel will continue to be the most vital material in sustainable construction – and improvements in its manufacture will only continue to improve. Research, innovation and renewable energy in manufacturing are also helping to make steel-making more carbon neutral to reduce steel’s overall carbon footprint. Summit Steel Buildings is committed to a sustainable future, and that’s why we expect structural steel to remain the most appropriate environmentally friendly building material for generations to come.

When you’re ready to expand your operations or build a new facility, look to Summit Steel Buildings to ensure you get the structure you need and one that’s intelligent for the environment.

We’re ready to build when you are.

About the author

Frank Melo has a construction engineering and business background with over 25 years of experience as a business owner and contractor. He was born in the Azores on the island of São Miguel and moved to London, Ontario at the age of two. After studying architecture, Frank graduated from Fanshawe College’s civil engineering technology program. He divides his time between projects primarily in Ontario and British Columbia. Frank can be contacted at Summit Steel Buildings at (778) 951-4766, by email at frank.melo@summitsteelbuildings.com or you can connect with him on

LinkedIn.