Buy Canadian: Domestic manufacturing creates value and offsets inflation risk

Summit Steel Buildings provides clients with ideal metal wall and roofing systems and components made in Canadian factories to ensure price and supply stability.

In a period of economic uncertainty, Canadians and engineering professionals are discovering that pre-engineered metal building (PEMB) solutions offer remarkable advantages because they can be sourced domestically. The challenges of international procurement – volatile exchange rates, complex logistics and unpredictable tariffs – have driven a shift toward local manufacturing partnerships. Summit Steel Buildings fosters strategic cost management through their network of Canadian factories to create economic and operational benefits for clients.

Advantages of domestic manufacturing

"By producing components within Canada at our manufacturing centers and as close to the jobsite as possible, we eliminate the risks and delays of cross-border complications," explains Darren Sperling, president of Summit Steel Buildings. The company, located in Vancouver, British Columbia, is Western Canada’s premier supplier of pre-engineered building solutions. Their localized supply chain approach yields multiple engineering and financial benefits for clients:

1. Optimize supply chains

The proximity of Canadian steel plants to project sites creates streamlined logistics that significantly reduces transportation costs and delivery times. This optimization becomes particularly valuable when managing complex project schedules and coordinating multiple deliveries.

2. Mitigate financial risk

For architectural and engineering firms managing multiple project budgets, working with a turnkey building provider that offers domestic manufacturing, like Summit Steel Buildings, creates several key financial advantages:

- Elimination of USD/CAD currency exchange rate exposure

- Avoid international shipping costs and documentation

- Reduce impact of unexpected tariffs, duties and customs fees

- Simplified tax structure.

Learn how you can leverage lower interest rates to reduce the cost of your building construction.

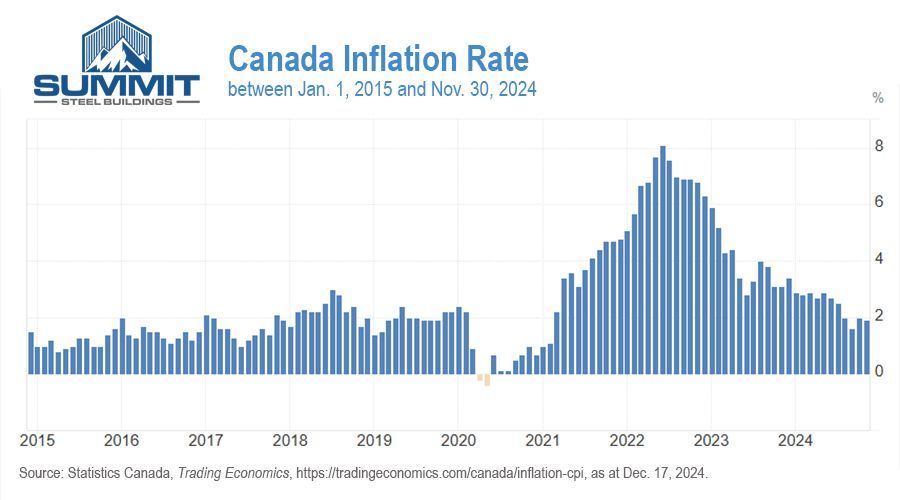

Inflation protection through strategic timing

Supply chain and economic pressures have forced firms to adopt new strategies to protect project budgets. Early procurement to lock in prices has emerged as an effective tool against material cost volatility and inflation. By engaging with Summit Steel Buildings early during the project planning phase, we can secure current pricing on future material and labor needs to help keep overall costs affordable, effectively creating a hedge against potential market increases.

Summit Steel Buildings offers exceptional value. Our local presence also means faster response times, smoother project execution and the peace of mind that comes from working with a company that understands the Canadian market.

While inflation concerns persist across the construction industry, ordering in advance protects against future construction cost increases. By choosing Summit Steel Buildings, you're not just getting a superior building – you're making a smart financial decision that hedges against market volatility and potential trade policy changes.

Project management and engineering considerations

For organizational decision-makers and management professionals evaluating pre-engineered metal building solutions, several technical factors support our domestic manufacturing approach:

- Simplified quality control through direct manufacturer relationships

- Reduced lead times enabling more responsive project scheduling

- Enhanced ability to accommodate design modifications

- Streamlined compliance with local building codes and standards.

Obtain an ideal price, fight inflation and protect project schedules

By working with Summit Steel Buildings as your premier pre-engineered construction and systems provider, we can integrate reliable and better-built close-to-site manufacturing into your project to improve sustainability, scheduling and cost-savings.

Using domestic building solutions produced in Canada represents a strategic approach to both technical excellence and supply management. By combining early procurement strategies with local manufacturing partnerships, our commercial, industrial, architectural and engineering clients receive superior construction results while earning the benefits of using current market conditions and economic factors to their favor.

For free quote and preliminary drawings suited to your specific location and business need, please use our webform, send us an email or call us at 877-417-8335. We're excited to speak with you and help develop your ideal pre-engineered building solution.

About the author

Darren Sperling has specialized in the engineering and delivery of pre-engineered steel buildings for over 15 years and has experience in over 20 countries worldwide. He can be contacted at Summit Steel Buildings at (877) 417-8335, by email at darren.sperling@summitsteelbuildings.com or on LinkedIn.