Steel helps build neighbourhoods through recreational centres

When healthy living and social engagement are community priorities, a steel building quickly becomes a vibrant and inclusive networking hub.

Healthy communities are united by inclusive and welcoming recreational centres to house a wide variety of activities and municipal programming. More and more, these important neighborhood centers are born as a planning outcome between not-for-profit organizations, private enterprise and municipal government. Volunteer and community groups are often tasked with the challenge of delivering recreational options under increasingly challenging budgetary constraints. Fortunately, building with a pre-engineered steel structure offers the economical and sustainable solution that communities need.

Today, recreation facilities aren’t just limited to providing a safe place for athletics. Public funds are now expected to serve a much wider variety of needs. Multi-purpose community centres are an expectation, complete with areas for crafting or artistic pursuits, meeting rooms, cafeterias and kitchens, changing and shower areas and office space with enough room for storage, operational logistics and administration.

More for your dollar: Making the most out of limited resources

For capital projects under greater scrutiny for getting the most out of a limited (or modest) budget, building with pre-engineered steel offers many benefits over using lumber or other traditional building materials. Steel buildings are more economical and offer more sustainability than using brick and mortar. Working with steel is generally 30% less than the price of traditional construction and takes about as third as long to complete.

When it comes to community- or government-funded projects, completion deadlines are critical. Steel buildings are quickly assembled with enhanced design options to establish your community centre as an attractive first-class venue for those looking to have an offsite business meeting, training seminar or community function.

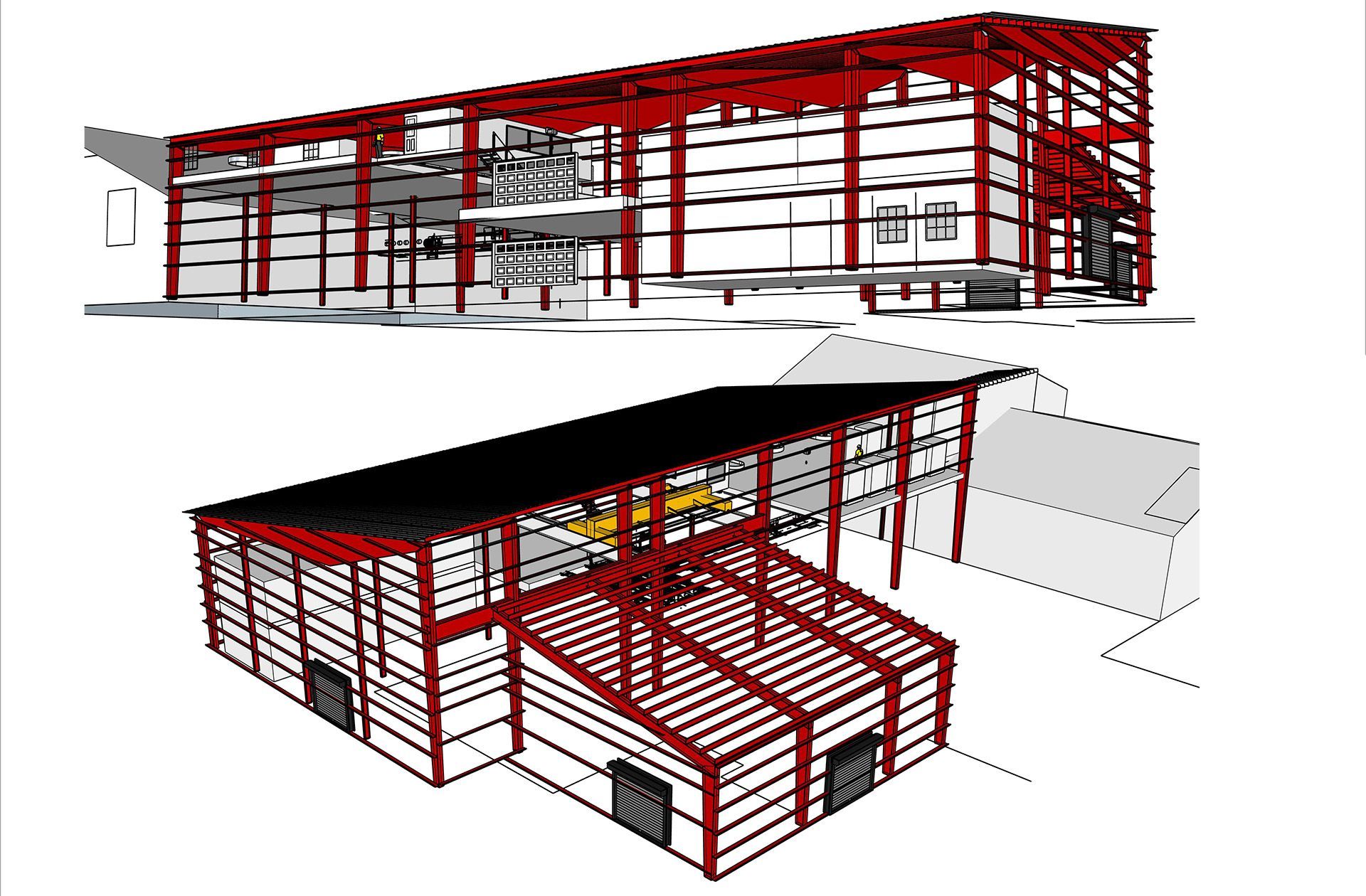

Summit Steel Buildings uses precision cut, pre-engineered panels (cold-formed and designed to accept any R-value insulation, including double layer systems, and a range of exterior finishes) that provide tighter seals to avoid leaks and produce less waste. Computer-aided design (CAD) aids in the production of flexible steel construction, allowing much of the labour to be done off-site, making on-site assembly more straightforward. These savings in time and materials are passed along to the client.

And the cost savings don’t end with construction. With almost endless potential for use, pre-engineered steel buildings provide lowered ongoing costs, in terms of lower utilities usage and little to no ongoing maintenance. Pre-engineered panels can also be inexpensively and easily replaced in case of accidents (as opposed to requiring massive structural repairs).

Don’t get locked into one structural footprint forever

Pre-engineered recreational steel buildings offer versatile options for design and floorplans while also offering greater potential for expansion or additions. You are no longer confined to a specific footprint that may require a sizeable investment to change as your special needs grow. Steel buildings’ modular engineering is designed to be quickly and cost-effectively expanded or repurposed to a variety of layouts as needs change.

The interior of your building can be updated at any time to accommodate new needs, including more rooms, office space and much more. Fitness and recreation centers can easily swap out equipment, add new classrooms, or remove rooms to create more open space. Steel’s high strength-to-weight ratio means wider open spaces without interior support beams. Many open concept uses become a possibility, especially to help house large gatherings with great sightlines.

Building communities while helping to save the planet

Municipal mandates and community concerns mean more attention is being given to the critical issues of sustainability, environmental stewardship and economic viability. Fortunately, steel manufacturing is becoming more efficient in using less energy to make more. The steel used in any of our final buildings can be made faster than traditional materials and is value-engineered using current best practices. Modern fabrication technology provides greater precision, productivity and safety.

Cold-formed steel in the pre-engineered panels uses less energy to create (processing is done at or near room temperature and results in a stronger and more resilient product to tension breaking and deformation). Pre-finished and treated steel panels eliminate the need for painting and help reduce more chemicals in the construction process. Increased durability and reduced costs aside, pre-engineered metal buildings are much more environmentally friendly than other building materials.

Steel is 100% recyclable. Once you're done with your building, it can be sold and moved or sold off to be used in another steel building. Few materials end up in landfill. Steel’s higher carbon content also traps it within the material during manufacturing rather than releasing it into the environment to result in a much lower carbon footprint.

Start building your inclusive community beginning with steel

With its focus on healthy living, fitness and neighbourhood involvement, your community centre or neighbourhood facility will become a model for how community, private and government partnerships can work. Support enriching lifestyles by creating a large community and social space for safe and affordable arts, cultural and recreational activities. From meeting rooms to community kitchens, dance studios to craft facilities, a steel building will provide the flexibility both inside and out to meet an abundance of activities. Contact Summit Steel Buildings today to get a free quote and to get started on your community building project.

About the author

Darren Sperling has specialized in the engineering and delivery of pre-engineered steel buildings for over 15 years and has experience in over 20 countries worldwide. He can be contacted at Summit Steel Buildings at (877) 417-8335, by email at darren.sperling@summitsteelbuildings.com or on LinkedIn.