More than a pretty face

Pre-engineered steel panels create strong exterior walls that will protect your investment from the harshest elements.

Written by

Frank Melo

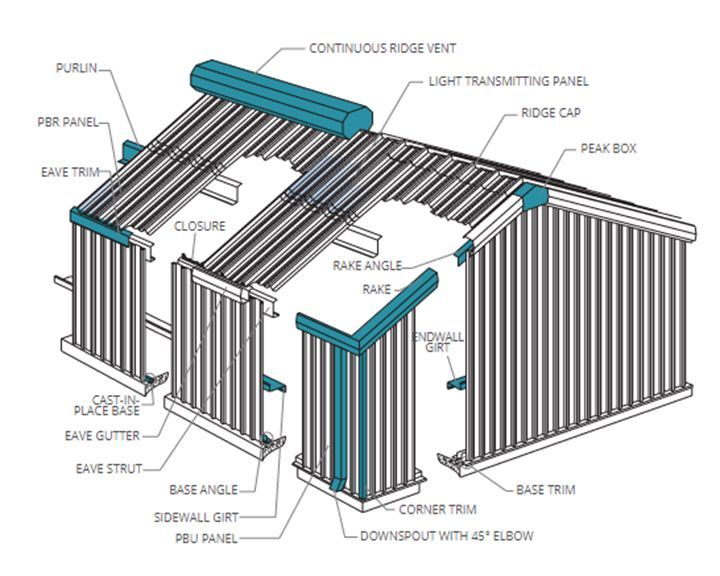

The durability and affordability of metal buildings is founded on the use of pre-engineered steel panels. These sturdy materials have become the standard for commercial structures and contribute to the evolution of modern industrial construction across Canada and the U.S. Exterior-facing cold-formed steel panels are strong, insulated, attractive (available in a wide variety of colours and finishes) and provide essential protection against the elements.

Clients appreciate steel panels for their low maintenance and cost-effectiveness. Engineers and builders prefer pre-engineered building solutions for their quality, durability and time-saving ease of construction. Meanwhile, architects prefer the versatility and the design potential they afford.

Summit Steel Buildings supplies leading pre-engineering components and wall panes across the continent to manage and erect the ideal business facility for clients. In this article, we’ll explore how pre-engineered steel buildings are your ideal solution.

Intelligent efficiency equals faster construction and less waste

Pre-engineering’s unique methodology involves manufacturing components off-site and shipping them to the jobsite where they can be quickly and easily assembled. This process saves overall construction time and lowers costs without sacrificing structural integrity and strength of the final building.

The benefit to your project is how it uses fewer tradespeople to reduce onsite labour costs. Materials are ordered and manufactured specifically for the needs of your unique construction project to create much less waste. Taking aside the environmental benefits of steel, metal buildings are much more efficient to use in construction compared to traditional building materials (such as timber or brick), reducing overall construction times by 75%. Shorter timeframes lower financing and insurance costs, allowing you to occupy the building sooner and start earning revenue on its use. Pre-engineered with steel panels also allow for construction in all four seasons (links to article from Double Black Construction – one of our preferred installation partners) and less downtime. All told, these savings can lead to hundreds of thousands off your total building project.

Pre-engineering and offsite construction make it possible

Cold-formed steel panels are manufactured in factories in advance of construction time and arrive pre-welded, pre-cut and pre-hole punched to reduce costs and construction times. The panels arrive ready to be installed, in your choice of a wide range of exterior finishes and ready to support any R-value insulation.

Using cold-formed steel is harder in tensile strength and has less surface imperfections (compared to hot rolling) to better resist bending and deformation. Precision manufacturing means components fit together better for enhanced stability in the final structure. Cold-formed steel’s strength as both structural elements, such as frames and beams, and as exterior panels is another reason the material has become so ubiquitous in commercial structures. Panels range from the basic mesa to enhanced fluted, embossed, striated, texture or exposed fastener utility style. Panels are fastened in a concealed fashion to create elegant designs and a more appealing finish.

Using pre-engineered panels won’t detract from the building’s final appearance. Buildings look much more modern and attractive because of their many design possibilities. One popular trend is to use pre-weathered steel or stainless steel to create an amazing look while eliminating the need for future painting. Pre-engineered metal buildings are available in a variety of colors, roof styles, and window options that can be customized to suit just about any design scheme. It is extremely easy to make your building blend in or stand out.

Colour schemes for exterior panels have been trending toward warmer tones. You have way more choice than grey, black, blue or other cool colours. Your steel building can incorporate any combination of colour, pattern or metal tone, including brass, copper, nickel or one of two dozen Pantone-inspired colours. Imagine the impression your building will make by incorporating natural or earth tones, or champagne and soft gold shades into your final aesthetic design.

Precision engineering creates better internal environments

Cold-formed steel components are manufactured to exact measurements to facilitate ease and efficiency in assembly on the jobsite. Imagine larger versions of Lego blocks: the construction process is less complicated, faster and improves quality of the build and stability. Precision engineering means components are sized to fit to an exacting degree. Measurements are within a narrow margin of error, usually in the range of micro measurements. No drafts, no leaks, no water seepage.

Buildings constructed with pre-engineered steel components and exterior panels increase the building’s resistance to extreme climates. Regardless of how hot or cold it gets on the outside, the interior of your building will be comfortable without any interruption. Steel framing also allows for large walls of windows to allow more natural light and can save on annual utility costs.

Industrial and commercial buildings needs to be tough and durable, while still looking attractive without expensive and time-consuming maintenance. Cold-formed framing and panels are designed with the structural integrity and all the plumbing, electrical and environmental controls to make your building perform at its best over the long run. Your pre-engineered steel building will be erected quickly, affordably to meet all your current and future needs.

Get the strength you need and the attractive look you want

Summit Steel Buildings offers the pre-engineered steel building solution you need for any industry and commercial purpose. Visit our project gallery to see the amazing structures that can be created using pre-engineered steel panel systems. As part of a complete custom-designed manufacturing process, using cold-formed steel panels as part of your overall pre-engineered framing and wall system offers a cost-effective and energy-saving building solution for any budget. Rely on steel panel’s attractive durability and protection against the elements to create an ideal setting for your business operation.

Summit Steel Buildings is your ultimate partner for all your building needs. As your one-stop building solution, we'll handle all aspects of the project on your behalf. We promise to complete your metal building project quickly and within the quoted price. So why wait? Share your requirements with us, and our professionals will transform your vision into a reality. Contact us now online, by email at info@summitsteelbuildings.com or at 877-417-8335 and we'll provide you with a free consultation and quote.

About the author

Frank Melo has a construction civil engineering technology and business background with over 25 years of experience as a business owner and contractor. He was born and educated in London, Ontario and now divides his time between projects primarily in Ontario and British Columbia. He can be contacted at Summit Steel Buildings at

(778) 951-4766 or by email at

frank.melo@summitsteelbuildings.com

or through

LinkedIn.