The timing is right for investing in steel building capital projects

A mix of economic and supply-demand factors make late 2024 the ideal time to pre-order metal structures.

Construction, like many other industries, has been subject to a tug and war between inflationary pressures and interest rate adjustments over the past few years. And while the outlook for Canada’s economy remains somewhat complicated, recent monetary and fiscal policies have been attempting to keep the economic forces in balance.

For businesses looking to expand operations or are currently anticipating what their production and storage space needs will be

[read about how more space increases productivity and creates other human resource gains], these economic moves have made autumn and winter of 2024 a good time to lock down your next building project. Reserving your capital expansion early with

Summit Steel Buildings will result in lower costs and operational savings for your company. It’ll also make you look like an expert in taking advantage of favorable economic opportunities.

The factors influencing the effectiveness of your cost of capital

Companies often finance their future needs by using reserves or taking on debt. The better use of resources – depending on the company’s preferred capital structure – is determined by weighted average cost of capital calculations. Usually this involves purchasing equipment that will produce more or bring down the cost of fabrication.

The purchase of fixed assets, such as new facilities and buildings, is different. Even though you won’t generate a pure return in the short run, the long-term appreciation and added value or return from using the space (either in increased production and sales, or lower inventory and storage costs) will quickly exceed the cost of the capital used to finance the project.

For companies that have been considering expanding their functional operating space by adding a new building, several changes in the economy are working in your favor – but they won’t last forever:

- Interest rates are dropping – Enjoy lower financing costs that will help drop your overall cost of debt.

- Steel prices have settled into 8-year lows – lower capital costs for your project.

- Entering the winter season – Benefit from the savings that happen when construction production slows down. [Check out this industry article about winter construction.]

Lower interest rates

Businesses love when interest rates drop, and their cost of borrowing is much less. The Bank of Canada reduced their rate by a quarter of a percent at the beginning of September, the third cut of 25 basis points since June 2024. Add to that, economists are predicting two more quarter percentage point cuts by the end of 2024.

The cuts were a measure to combat rising inflation which seemed to have worked. Inflation climbed to 6.8% in 2022 but fell to 3.9% for 2023 and has dropped to 2.5% since (source). Material costs remaining steady for a while mean it’s a good time to buy and invest.

Steel prices

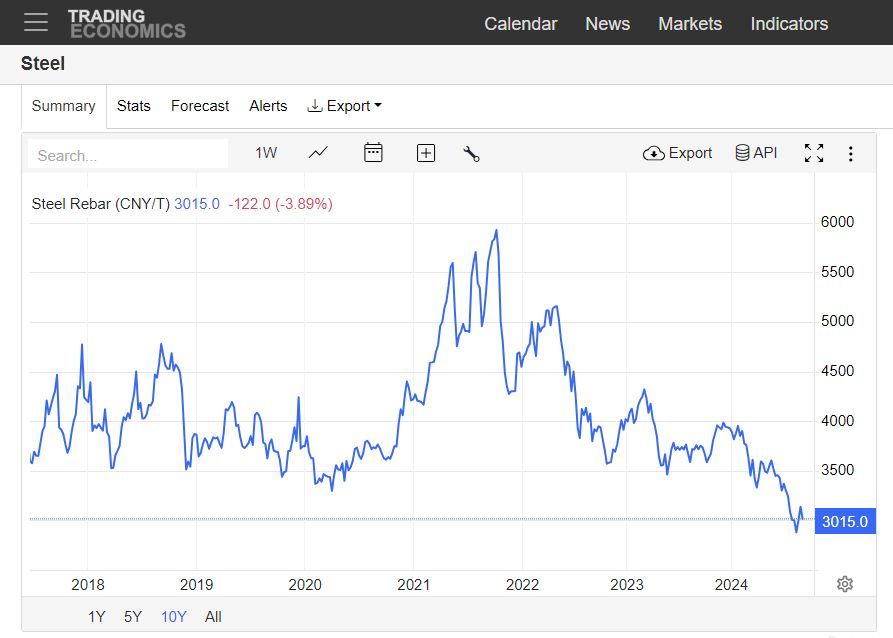

It is a fantastic time to commit to building metal facilities because the cost of materials hasn’t been this low in years. Steel rebar futures are an important measure for metal prices within the construction industry. These futures have fallen 23% year-to-date and are sitting at the best price since 2017 (source).

Fabricated metal products and construction materials are down from July 2022 highs (144.5 down to 139.4). By contrast, cement, glass and other non-metallic mineral products are up substantially over the last two years (113.0 in July 2022 to 136.6 in July 2024, according to Statistics Canada industrial product price index (source).

Another good reason to reserve orders now on new metal buildings: recent trade spats with China are going to affect future domestic steel prices. To combat suspected Chinese trade dumping, Canada set a new tariff on imported aluminum and steel. According to the

Globe and Mail, “the 25-per-cent surcharge that will apply to Chinese exports of aluminum and steel as of Oct. 14 will put upward pressure on prices paid by Canadian businesses

(source).”

Winter manufacturing and pre-engineering

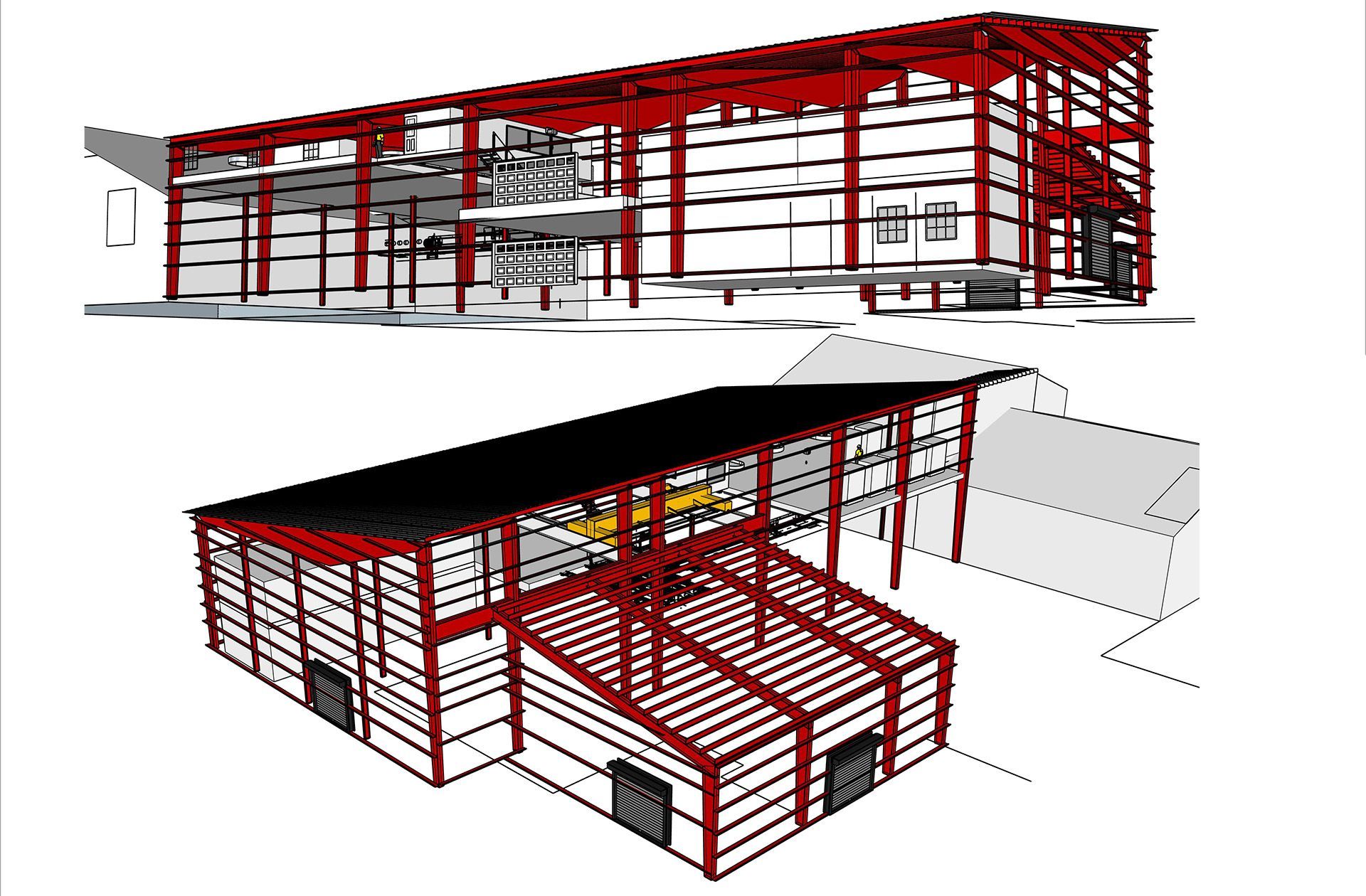

A great deal of production and engineering work goes into a metal building construction project well before the site for cleared and foundation work begins. Every structure Summit Steel Buildings is custom made for clients and their unique business needs. All the framing and components are manufactured well in advance in a system that was originated by Gustave Eiffel’s firm and used in the construction of his famous tower.

With pre-engineering processes and manufacturing completed during wintertime, your building can be fast-tracked to the start of spring, meaning once the foundation has been prepared, the steel framing can be installed immediately. And with components already to go, they can be shipped to the site and installed as soon as the weather permits. This streamlined process means your construction costs are 30% less than the price of traditional construction – and can be completed in about a third of the time.

Get a jumpstart on your completed building by taking advantage of current conditions

Pre-booking your steel project to take advantage of current lower prices is always a smart decision. It locks you into a set price that won’t increase with the market and helps our team plan material orders to take advantage of better pricing and schedule our production.

Contact us today to get started on your next structure. Take advantage of this market timing with a phone call to 877-417-8335 and receive your free quote and preliminary drawings.

About the author

Darren Sperling has specialized in the engineering and delivery of pre-engineered steel buildings for over 15 years and has experience in over 20 countries worldwide. He can be contacted at Summit Steel Buildings at (877) 417-8335, by email at darren.sperling@summitsteelbuildings.com or on LinkedIn.