Celebrating purlins: the steel component that raises the roof

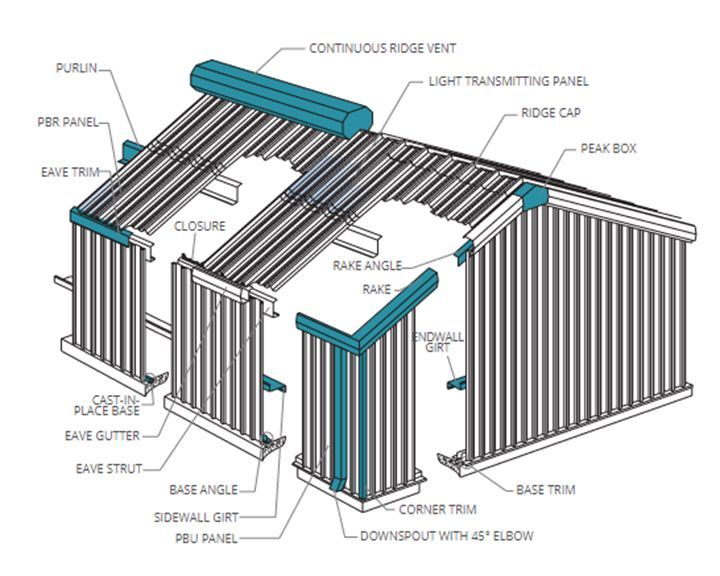

Purlins are essential components in metal building construction, acting as horizontal beams that provide support for the roof. It’s a horizontal structure member that supports the roof covering. Here’s what building clients need to know about purlins.

What are purlins?

Purlins are used to support the loads from the roof deck or sheathing and transfer them to the primary structural frame. Purlins are positioned parallel to the building eaves and span the length of the roof, sitting on top of the rafters or between the spaces of the rafters.

Their function is to provide stability and strength to the roofing system. In some cases, clamps can be added to secure the roof to prevent it blowing off in the case of super high winds, such as with hurricanes and tornadoes. Not every building is going to need to be secured so tightly as the massive weight of roofing is enough to keep the building engineering secure and in place.

Purlins usually are designed in one of two types: C- and Z-purlins based on their shape.

- C-purlins resemble the letter ‘C’ and are commonly used for wall and floor joists. They are ideal for handling lighter loads are easier and faster to install. Their versatility and design make them more economical.

- Z-purlins are unsurprisingly shaped like the letter ‘Z’. They are more often used in roofing applications and create a continuous line of support because they overlap. As a result, they are stronger than C-purlins and more suitable for larger and more industrial purposes. Z-purlins allow for longer spans and heavier loads.

Regardless of their shape, purlins are typically made from high-quality steel to ensure durability and strength. They are often galvanized or coated with other protective materials to resist corrosion and extend their lifespan.

The benefits of using purlins

Because purlins reduce the need for closely packed rafters, they are cost-effective and lower material costs. Summit Steel Buildings relies on purlins to help manage overall material and construction costs to keep their prices affordable and more reasonable for clients.

Purlins are versatile meaning they be used in a variety of building projects with a wide assortment of building types, especially in commercial and industrial structures. As with most pre-engineered components, purlins can be

prefabricated off-site in advance to help speed up the construction process. At the site, they are easy to install, which helps to lower labour costs for clients. Purlins’ durability provides long-lasting structural support,

reducing the need and cost of regular maintenance.

What is considered when manufacturing purlins

While most clients won’t give a thought to the type of purlins to be used (or that they’re even part of the building), Summit Steel Buildings spends the time to ensure that only the best engineered metal parts of the highest structural integrity are used throughout the structure. This includes purlins.

Because you can see the purlins underneath the roofing system, how they look is important. When clients choose their exterior materials and colours, it is also applied to purlins, so the building looks cohesive and impressive to guests and the general public alike. Other factors about purlins are also taken into account:

- Load requirements – We ensure purlins are designed to handle the specific load requirements of each specific building based on dimensions and overall weight.

- Span and spacing – Proper span and spacing are crucial for optimal performance so Summit Steel Buildings consults with structural engineers to determine the best configuration.

- Quality and standards – Purlins must meet industry standards, so Summit Steel Buildings only supplies cold-formed steel components that are manufactured in four factories throughout North America to assure strength and reliability.

Understanding the role and types of purlins is essential for clients to help them make informed decisions about their future building. Well-made metal components, framing, panels and parts ensure structural integrity and cost-efficiency. Clients can trust in Summit Steel Buildings’ engineering for all their components to assure quality construction that creates a dependable structure that will last for decades.

About the author

Darren Sperling has specialized in the engineering and delivery of pre-engineered steel buildings for over 15 years and has experience in over 20 countries worldwide. He can be contacted at Summit Steel Buildings at (877) 417-8335, by email at darren.sperling@summitsteelbuildings.com or on LinkedIn.