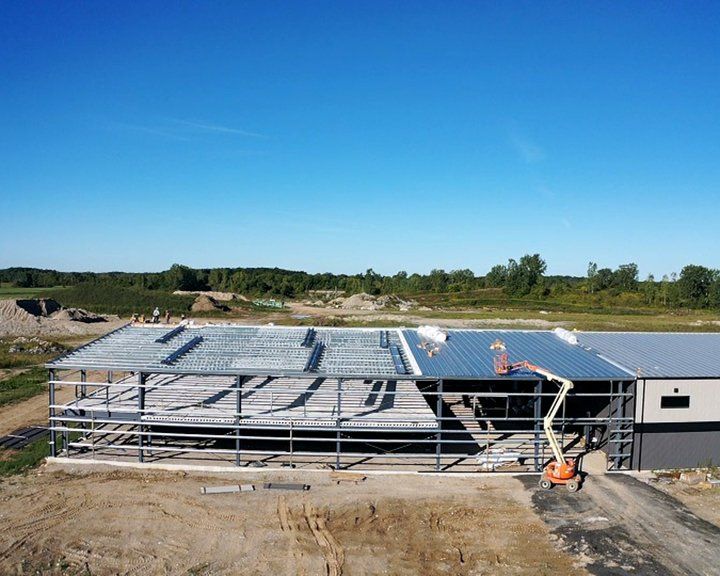

FCMP Outdoor building expansion construction gallery

Pre-engineered metal buildings are affordably expandable.

After building an initial 49,000-square-foot headquarters, gardening company chooses Summit Steel Buildings for subsequent expansions. Jobsite photos give you a behind-the-scenes first look at the most recent addition.

After breaking ground in June 2022, construction work on the latest 35,000-square-foot addition to the FCMP Outdoor headquarters has progressed quickly.

The Thorndale, Ontario lawn and garden product company manufacturers a popular (and top-ranked,

according to Amazon) line of composters, rain barrels and planters. The sales demand for their environmentally friendly materials created a need to increase their operational space. Fortunately, when FCMP Outdoor (also known as Forest City Models and Patterns) first built their existing structure using Summit Steel Buildings’ pre-engineering system, open-ended modular framing meant that additional expansion could be done quickly and affordably.

FCMP Outdoor is a repeat client

The results of the original build were so successful that this expansion is actually the second addition Summit Steel Buildings has provided at the site. The initial building, completed in July 2017, is 140’ x 350’ and includes two-floors of office and administration space, manufacturing and storage area and four loading bays. The first extension in 2019 added another 28,000 square feet of space (140’ x 200’) and four more loading docks. The recent 21,000-square-foot work (140’ x 150’) also includes a second-floor mezzanine of 100’ by 140’. Steel’s high strength-to-weight ratio means the facility is all open space, with wide clear spans and no pillars to obstruct traffic flow patterns and plenty of area for product and materials inventories.

Pre-engineered metal buildings are designed to be affordably expandable

Summit Steel Buildings has an enduring partnership with FCMP Outdoor for meeting their building needs. Two successful expansion projects are testament to the continuing quality of work and their satisfaction with the original craftsmanship. The benefits of using pre-engineered steel building support FCMP Outdoor’s building decisions.

- What size building do you need?

- Warehousing space has never been more critical

- The importance of increased working space

- Recognize the signs when it’s time to increase business space

Clients never need to worry about outgrowing your building space. Steel buildings make adding future development quick and inexpensive by adding onto existing length with additional modular units. Rest assured you’ll be able to address future capacity without being locked into an existing brick and mortar or mass timber construction. It’s one way you can address future needs without compromise. Working with steel is generally 30% less than the price of traditional construction and takes about as third as long to complete. These efficient construction allowed FCMP to utilize the new space more quickly without interrupting business operations.

Let Summit Steel Buildings design your next building

Pre-engineered metal buildings offer the flexibility you want no matter the size of facility you need. Our rigid-frame system means your project can be completed faster and at less cost than with traditional concrete and wood construction. Summit Steel Buildings is your single point of contact throughout all stages of project management, from design to completion. We’ll help turn your vision into reality and ensure your steel frame construction turns out exactly as designed. Speak with one of our representations to get started. We look forward to helping you determine the size of building you need.

About the author

A. Paul Mitchell is the Marketing Director for Summit Steel Buildings and is an award-winning marketing professional with over 30-years experience in design and corporate communications. His previous cross-industry experience has helped develop an extensive breadth of skills, including writing, graphic design, web design, media relations and photography. Paul holds a Bachelor of Arts degree, is an MBA candidate and holds professional certificates in Leadership and Business Analysis from Western University. He also completed Centennial College’s post-graduate marketing and business management program. He lives in London, Ontario with his family.