GET A FREE QUOTE TODAY - CALL US

877-417-8335

It’s all about the girt – so essential in ensuring stability of wall panels

Most people have never heard of girts, or know what they are. Learn about the importance of this metal part in our

ongoing series about the components used in steel building construction.

The strongest and most secure industrial and commercial buildings are made with solid steel components for good reasons. They are quick to install, require little maintenance and retain their attractive appearance for decades. Not every part gets the attention it deserves when employees and visitors are taking a tour and are impressed by the scale and beauty of your building. It’s one of the reasons the team at Summit Steel Buildings decided to shine a light on some of the lesser-known parts we supply when we build your ideal pre-engineered facility.

Girts, for instance. Wait… What is a girt?

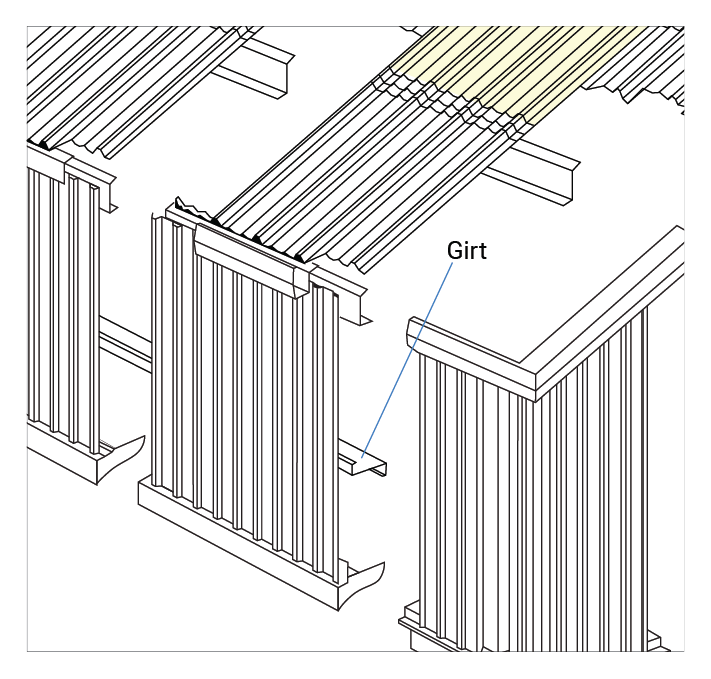

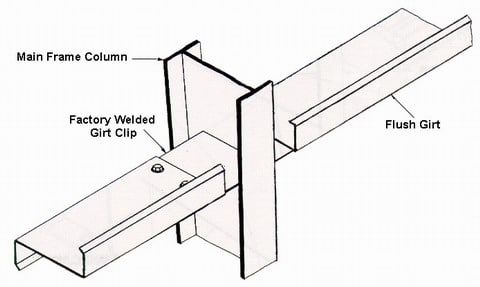

A girt is a horizontal structural steel member used to provide lateral support to the wall panels. They help transfer weight loads from the wall panels to the pre-engineered steel building’s main structural frame. In practical terms, they are the sideways bars that run along behind the walls to attach to column frames and connect to panels. Usually, you’ll find several running parallel to the ground every few feet up. Girts are essential in ensuring the stability and integrity of the building's exterior walls by resisting wind and seismic forces. They also contribute to the structure’s overall strength and rigidity.

How are girts installed?

Girts are placed horizontally between the building’s main vertical framing members (columns). They are usually spaced at regular intervals along the height of the wall, depending on the design requirements and the load they need to support. Spacing and size of girts are determined by factors such as the building’s dimensions, type of wall panels used and expected weight loads.

Importance and use in pre-engineered steel buildings

- Structural stability: By providing lateral support and transferring loads to the main frame, girts contribute significantly to the overall strength and durability of the building, as well as resistance to external forces.

- Wall panel support: Girts ensure wall panels are properly supported and securely attached, which is crucial for the building’s exterior integrity. They also ensure the building’s exterior cladding remains securely in place.

- Load distribution: They help in evenly distributing weight loads across the building’s structure, preventing localized stress and potential structural failures. Girts help transfer stress and weight loads to the primary structural frame of the building by distributing forces evenly.

- Panel attachment: Girts serve as attachment points for insulated metal wall panels, ensuring they are securely fastened to the building structure.

- Reinforcement: By connecting columns horizontally, girts add stiffness to wall systems, helping to prevent the building from twisting or warping under higher stresses and exterior forces.

The key characteristics to know

The choice of girt type depends on the specific engineering needs of the building, such as span length, load requirements, and design considerations.

- Shape: Girts are designed in various cross-sectional shapes, with the most common being Z-shaped (Z-girt) and C-shaped (C-girt).

- Z-girts: Shaped like the letter "Z," these are the most common type of girts used in metal buildings. They are efficient in load transfer due to their shape, which allows them to overlap, providing continuous support along the building's length. Z-Girts are preferred in areas where load distribution and continuity are critical. Their shape allows for an easy overlap that strengthens the connection between adjacent girts, making them ideal for larger buildings.

- C-girts: These have a C-shaped cross-section and are typically used for shorter spans. They are easier to install but are less efficient in supporting weight compared to Z-Girts. C-girts are used in situations where shorter spans or simpler connections are needed. They are typically utilized in less demanding structural scenarios.

- Hat girts: Hat-shaped girts are used less frequently and mostly in specific applications where additional spacing between the cladding and the structural frame is needed. Their shape allows them to provide a gap between the two surfaces. Hat Girts may be used in applications requiring special consideration for insulation or ventilation, as their profile allows for extra space.

- Positioning: Girts are installed at regular intervals along the height of the building, running horizontally between the columns. They form a frame onto which the exterior wall cladding or panels are attached. They can either be flush (lie directly against the surface) or bypass (leaving a little space as a moisture barrier).

- Materials:

Girts are best made from steel for strength and durability, often coated or galvanized to resist corrosion.

The strength of wall supports and girts comes from using steel

Girts are essential components in the framework of pre-engineered steel buildings, providing necessary support for exterior walls and metal panels, aiding in load distribution and contributing to overall stability. They serve multiple roles for horizontal support and maintaining rigidity of wall systems. Their proper design and installation are crucial for the durability and safety of your metal building.

When it comes time for your next industrial or commercial building, you don’t need to be expert in all the metal components used in your structure. It is definitely a good choice to partner with an experienced pre-engineered building partner, like Summit Steel Buildings, to supply all the engineering details you need for a successful project.

Contact our experienced pre-engineered building solution team online, by email or by calling us at 1-877-417-8335 to obtain a free quote and preliminary drawings.

About the author

Darren Sperling has specialized in the engineering and delivery of pre-engineered steel buildings for over 15 years and has experience in over 20 countries worldwide. He can be contacted at Summit Steel Buildings at (877) 417-8335, by email at darren.sperling@summitsteelbuildings.com or on LinkedIn.